Mahle Microchannel Heat Exchangers: Revolutionizing Heat Transfer

Microchannel heat exchangers have become integral components in various industries, revolutionizing the way heat is transferred and managed. Among the leading innovators in this field is Mahle, a company renowned for its cutting-edge technologies and solutions. In this article, we delve into the world of Mahle microchannel heat exchangers, exploring their significance, applications, advantages, and future prospects.

Introduction to Mahle Microchannel Heat Exchanger

In today’s fast-paced world, efficient heat exchange microchannel heat exchanger is critical across numerous sectors, including automotive, aerospace, and HVAC systems. Mahle microchannel heat exchangers offer a sophisticated solution to meet the ever-growing demand for enhanced performance and compact design.

Understanding Microchannel Heat Exchangers

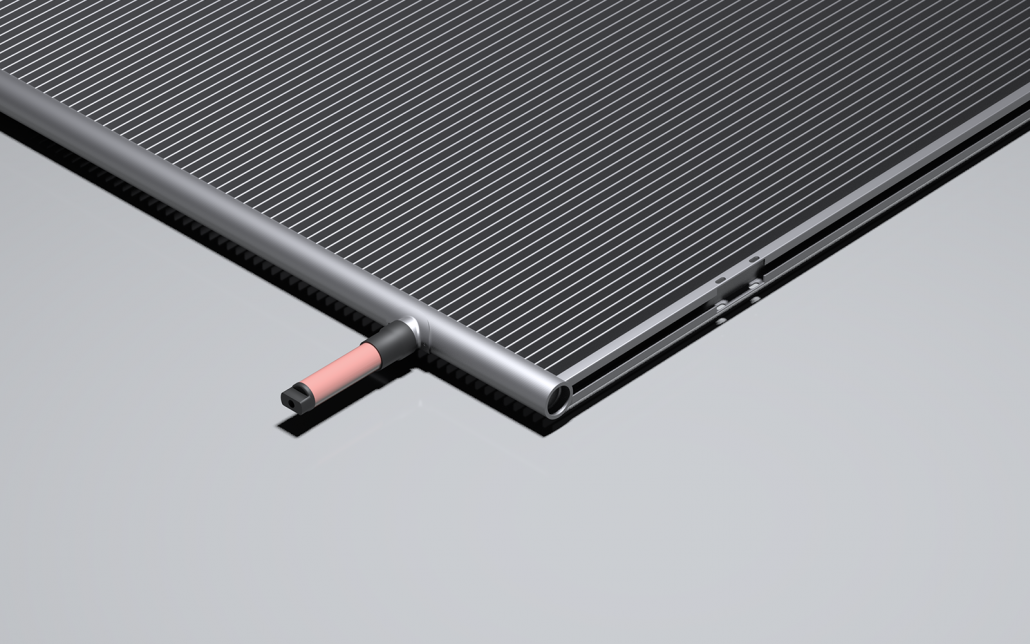

Microchannel heat exchangers, as the name suggests, utilize a series of small channels to facilitate heat transfer between fluids. Unlike traditional heat exchangers, which rely on larger tubes or plates, microchannel designs optimize surface area and fluid dynamics, resulting in improved efficiency and thermal management.

Advantages of Mahle Microchannel Heat Exchangers

Mahle microchannel heat exchangers boast several advantages over conventional counterparts. Their compact size allows for space-saving installations, ideal for applications with limited footprint requirements. Additionally, the enhanced heat transfer capabilities translate to higher efficiency and reduced energy consumption.

Applications of Mahle Microchannel Heat Exchangers

The versatility of Mahle microchannel heat exchangers makes them indispensable across various industries. In the automotive sector, they play a crucial role in cooling systems, improving engine performance and fuel efficiency. Similarly, HVAC systems benefit from their compact design and superior thermal properties, ensuring optimal indoor comfort.

Technical Innovations in Mahle Microchannel Heat Exchangers

Mahle continually pushes the boundaries of innovation, leveraging advanced materials and manufacturing techniques to enhance the performance of microchannel heat exchangers. From optimized geometries to tailored solutions for specific applications, their commitment to technological advancement sets new standards in the industry.

Environmental Impact and Sustainability

In an era focused on sustainability, Mahle microchannel heat exchangers offer significant environmental benefits. By improving energy efficiency and reducing greenhouse gas emissions, they contribute to a greener future while meeting the stringent regulatory requirements imposed on modern industries.

Challenges and Limitations

Despite their numerous advantages, Mahle microchannel heat exchangers face challenges such as cost considerations and maintenance requirements. However, ongoing research and development efforts aim to address these issues, ensuring continued advancements in performance and affordability.

Future Outlook

Looking ahead, the future of Mahle microchannel heat exchangers appears promising. With ongoing advancements in materials science, manufacturing technologies, and computational modeling, we can expect even greater efficiency, reliability, and versatility in the years to come.

Conclusion

In conclusion, Mahle microchannel heat exchangers represent a paradigm shift in heat transfer technology, offering unparalleled efficiency, compactness, and sustainability. As industries strive for greater performance and environmental responsibility, these innovative solutions continue to drive progress and shape the future of thermal management.